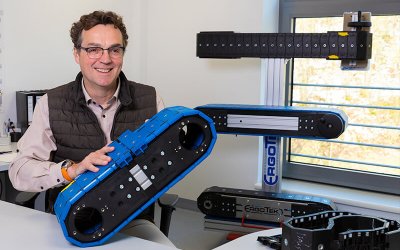

ESD conveyor systems – conveyor technology solutions for the transportation of automotive components

You need strong partners for ESD!

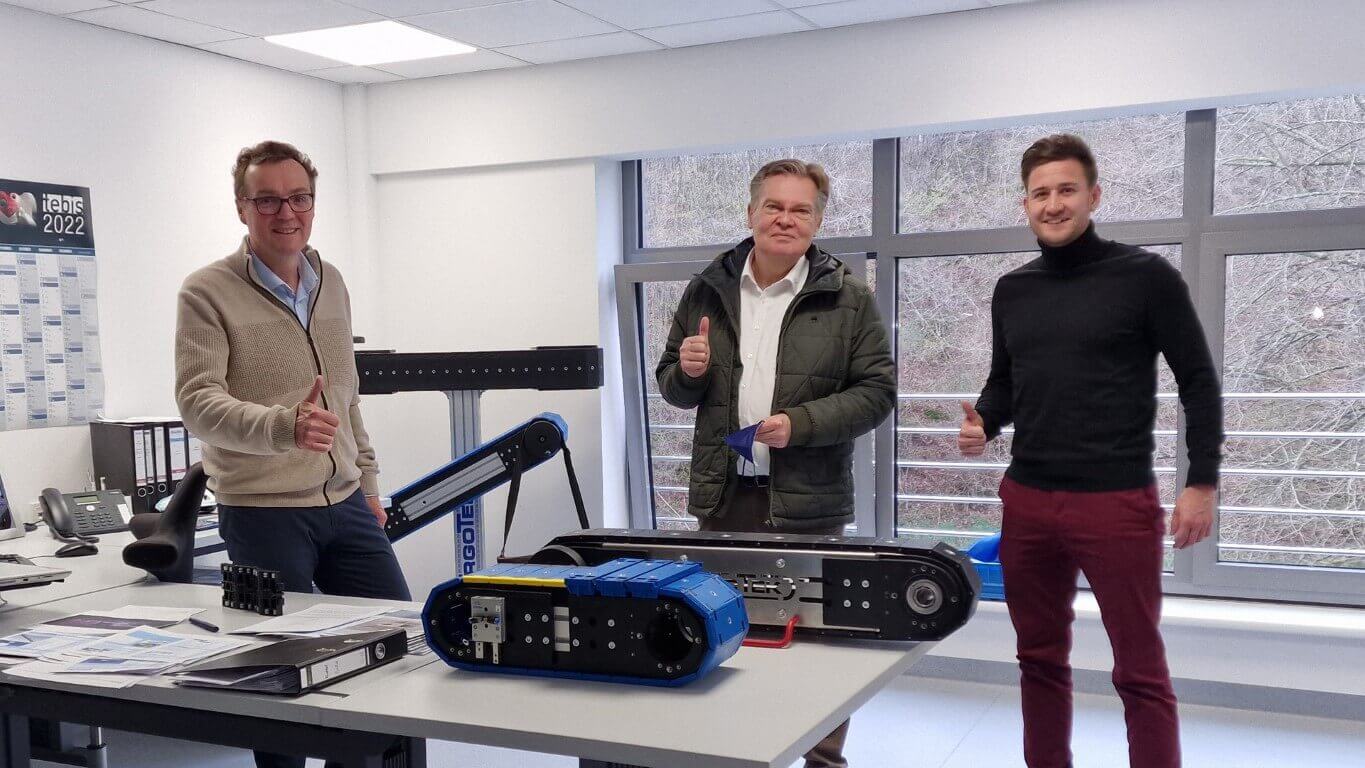

Many thanks to Hans-Joachim Felser and Björn Menneke for their professional support!

ESD-capable conveyor systems are becoming increasingly important.

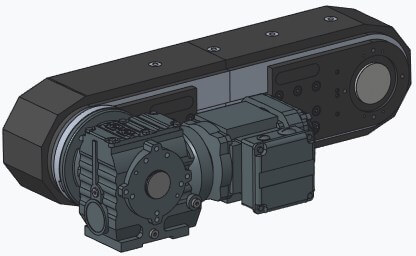

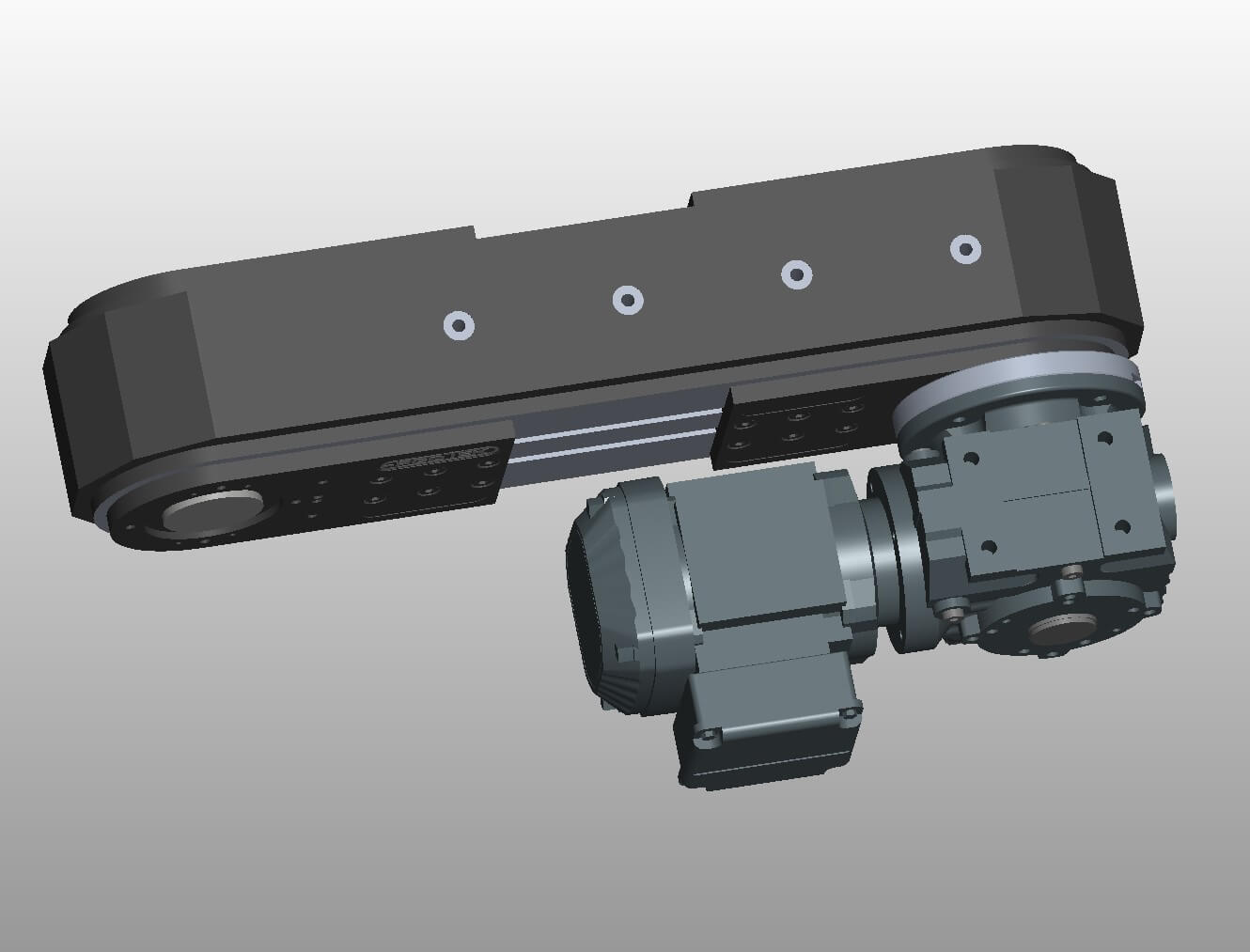

In many production process applications in the field of automated transportation of automotive components, e.g. in electronics or battery production, the conveyor systems used must be prevented from becoming electrostatically charged. This prevents damage to the components during transportation through the conveyor system due to electrostatic charging. Consistent conductivity of the conveyor systems is a prerequisite for this. The slide rail plays a decisive role in the material mix of belt body, slide rail and modular chain. It must meet both mechanical and electrical requirements.

In close cooperation with Murtfeldt, we have optimized and further developed our products for ESD-compliant use.

Our indexing conveyors and accumulating pallet circulation systems are also available in an ESD-compliant, dissipative version and can be optimally integrated into complex interlinking systems.

The measures against electrostatic discharge are varied and extensive.

In addition to an ESD-capable design of the conveyor systems, whose components are electrically connected to each other and also earthed, further measures must be taken in the production process:

- Wrist earthing straps for operating personnel

- ESD clothing for insulating personal items of clothing

- Dissipative work surfaces and furnishings

as well as e.g. worktops, chairs, shelves,… - ESD-compliant tools, devices and materials

- Dissipative floor coverings and footwear

- Ionizers

- Protective packaging

Contact us, we will be happy to support and advise you on all questions relating to conveyor technology and individual solutions for the special requirements of your components in ESD-compliant conveyor system transport!