The coronavirus crisis is presenting many companies with historic challenges. Happ Kunststoffspritzgusswerk und Formenbau GmbH has not only quickly found a way to adapt to the new situation, it has even developed its own certified respiratory protection mask, “Happy Breath”. This reflects the top management’s innovation-driven approach of constantly generating new sales markets through its own ideas. Automated production processes and a high level of vertical integration do the rest.

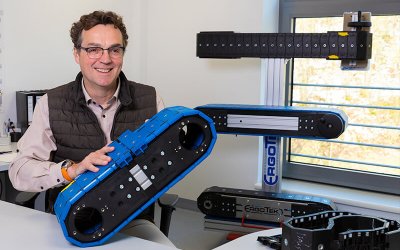

Change is in the blood of this company, which was founded in 1964: its initial focus was on the production of sandwich tins and furniture fittings. This was followed by specialization in plastic injection moulding products. Due to the company’s dependence on individual branches of industry, the management repeatedly generated alternative products and markets. Happ created various systems and the associated components in the field of mechanical engineering. Since 2018, the portfolio has included modular chains, conveyor systems and innovative small load carriers, products that are largely responsible for the company’s progress.

More sales thanks to innovation

In March 2020, the company developed protective equipment to combat the coronavirus pandemic. The “Happy Breath” FFP2 respirators have replaceable, sustainable filter elements with an easy-to-disinfect carrier system in two versions: During work, the mask can be worn comfortably and ear-relieving with the head strap; optionally, the mask can also be switched to ear loops. Happ has been supplying the German government with these FFP2-certified masks since October 2020. “We assume that we will be able to significantly increase our turnover with this product group,” says Managing Director Ulrich Berg.

All competencies in one hand

The primary goal of thinking and acting at Happ is the development of innovative concepts for tool production. So you design and build the tools for production yourself. The production processes are automated to the maximum and the development and construction of the systems are also carried out in-house. “Thanks to this constellation, we are able to design the production processes extremely effectively,” says Ulrich Berg. Potential innovations are often discussed, decided on and implemented by the development team at short notice. Deviations from the planned results are corrected and evaluated at short notice. “In this way, our own expertise grows and third parties do not have access to our innovation details,” explains Ulrich Berg. This also demonstrates the hands-on mentality at Happ.