3rd Technology Day | April 4, 2025 | Rinteln

On April 4, 2025, we will be exhibiting at the 3rd LTL Mechanical Engineering Technology Day –

under the motto “Germany’s future: Automated and innovative” in Rinteln.

You can look forward to informative specialist lectures, interesting presentations

and in-depth information from a wide range of well-known companies

on the core topic of automation and innovation

at the “smallest” industrial trade fair in Germany at LTL Maschinenbau in Rinteln.

Vertical buffer systems

An important contribution to the automation of your production applications is the optimization of your production processes. ErgoTek develops buffer systems that are specially tailored to your needs and can be flexibly integrated into your production process, adapted to your available space and requirements.

In the system example, we show a buffer that we have designed vertically due to the limited space available.

The task was to ensure uninterrupted and therefore automated production on a plastic injection molding machine. The vertical buffering ensures that the injection molding machine can produce continuously, even when the worker takes a break or is busy with other work.

When the manual workstation is not occupied, the pallets are clocked into the finished parts buffer. The worker can then process the parts from the finished parts buffer – the empty workpiece carriers are checked back into the empty buffer. This means that the worker is not tied to the machine cycle and can take on other tasks to ensure that the injection molding machine works continuously. This is very important, as interruptions result in NOK parts and rejects.

Your advantages

- Flexibly customizable pallet storage (component size, capacity, load,…)

- Vertical buffering

- High autonomy

- High quality thanks to constant production conditions

- Space-saving layout

- Simple and secure connection of the pallet holders

- Low maintenance / free of lubricants

- Problem-free integration

Conveyor technology all-rounders

Let us convince you of our conveyor technology solutions and find out more about the automation potential offered by our modular cycle and accumulating conveyors with individually usable workpiece carriers to optimize your production application during a personal consultation.

All ErgoTek conveyors are variable in length and width and can be operated in all installation positions. Various basic systems are available for safe and product-friendly workpiece transportation, with which we can guarantee optimum adaptation to your production requirements. If required, we can of course also develop and supply product-specific component holders.

FlexiTek pallet circulating conveyor systems

Interested?

Then register quickly. We look forward to your visit!

Occupational safety – circulation with magnetic pallets

SAFETY is a top priority for us and is adapted to your production application! Enclosed conveyor drives, the safely designed ErgoTek modular chain, magnetic workpiece holders – our options and ideas are diverse!

Watch the video to see our possibilities and ideas for yourself.

Interested?

Then secure one of the limited one of the limited Technology Day places.

We look forward to your visit!

Would you like to plan your Technology Day visit in advance?

We are happy to arrange an appointment now.

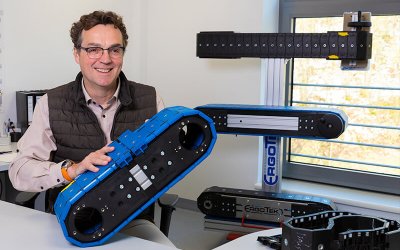

Dirk Wevelsiep

Managing Director

ErgoTek GmbH & Co. KG