Plastic chain conveyors – Transport and conveyor belts based on ErgoTek plastic modular chains offer many advantages!

With our selected and renowned plastic injection molding partners , we are able to develop custom-fit plastic chain conveyors – the ErgoTek plastic modular chain – for your production application.

The advantage of ErgoTek plastic modular chains lies in the maintenance costs of your production systems. The plastic modular chains are low-maintenance and can be used without lubricants, yet they are robust and durable in everyday operation.

In addition, our plastic chain conveyors can be used in both reversing and pushing mode and guarantee slip-free, safe and clean transportation of your production goods, including ESD-compliant.

The component mounts can be customized and are easy to install. Changeover times for short product cycles can also be significantly reduced as a result.

Example application plastic chain conveyor

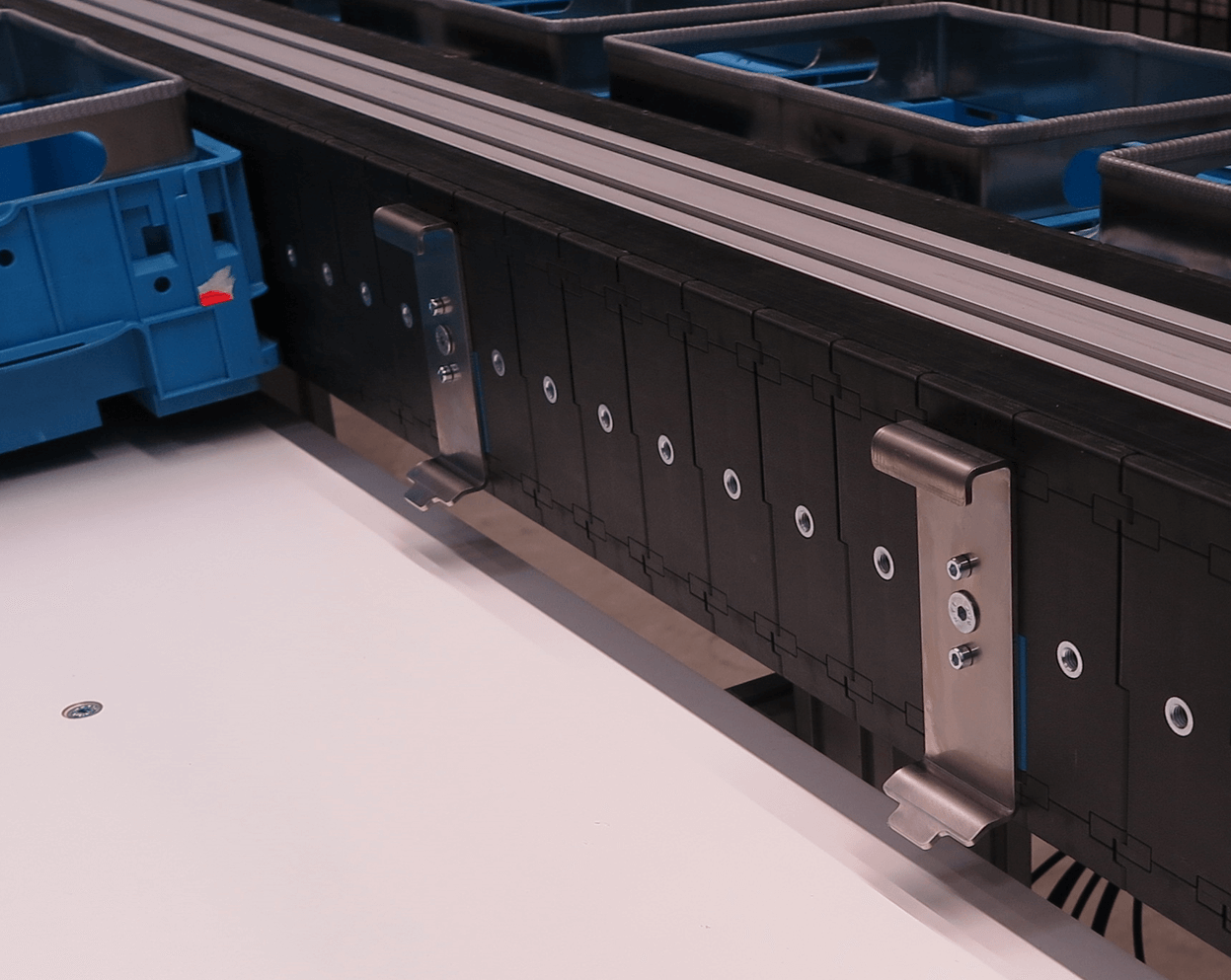

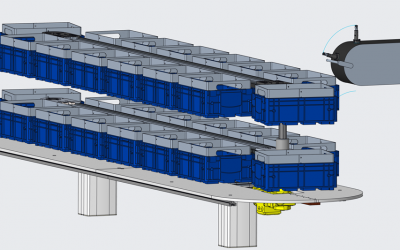

In our customer application, two plastic chain conveyors are used to feed and return a processing cell.

In the feeder (narrow belt), the components are fed in at regular intervals. The non-slip grip of the ErgoTek plastic modular chain ensures precise and easy positioning at the end of the infeed conveyor. (Shown here in the test by KLTs).

Different components can also be easily synchronized and positioned using a graduation sensor that supplies pulses synchronously with the “55_120” module chain. This is a simple and safe solution, especially for components that are difficult to detect.

The total load feed here is 15 components of approx. 15 kg each = 225 kg

High loads are transported by pushing in the return conveyor (wide belt). Here, too, the timing is carried out via a dividing sensor that clocks the finished parts out of the cell. Due to the available space, the drive could only be accommodated in the cell.

The total load feedback is at least 15 components á 20 kg = 300 kg

Up to approx. 1t possible in normal operation!

Even heavy components can be sensitive and must be transported carefully and safely. Always on the safe side with plastic modular chains from ErgoTek!

Advantages of plastic chain conveyors

- Low maintenance

- Free from lubricants

- Robust

- Reversing or sliding operation

- Slip-free transportation

- Simple mounting of recordings

ErgoTek plastic modular chains at a glance

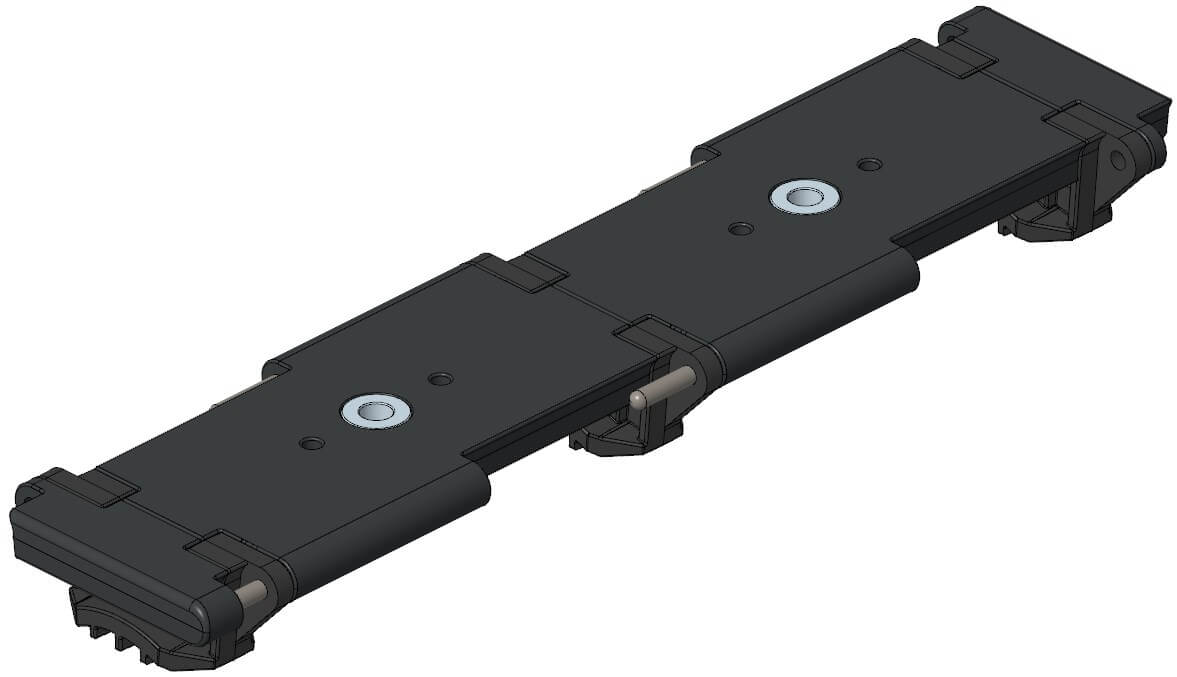

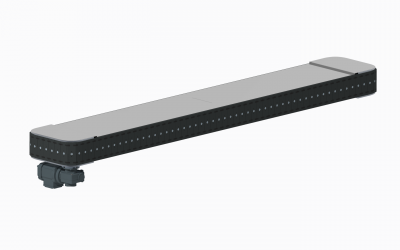

Our plastic modular chains – plastic chain conveyors optimized for your application – are ideal for your production application thanks to their space-saving design. Reliable handling of small to medium-sized parts, flexibility and short changeover times as well as simple integration into your machines and systems for a wide range of production applications are the top priorities here.

Our plastic modular chain conveyor is state-of-the-art and meets all the requirements of modern production processes. The control system is designed for simple and variable integration into your processes.

ErgoTek plastic modular chains have very good cleaning properties. They are also resistant to many chemicals and particularly wear-resistant.

Do your products need to be electrostatically protected? We also have solutions for ESD-compatible transportation!

The module chains are produced by selected and renowned plastic injection molding manufacturers – Made in Germany. This enables us to provide consistently high quality and short delivery times.

Technical specifications of our plastic modular chains:

- Module chain load: from 0.1 kg to 2,500 kg

- Module chain speed: up to 75 m/min

- Module chain width: 100 mm to 3200 mm

- Module chain length: 450 mm to 20,000 mm

- Optional: ESD

- Optional: can be accumulated

- Optional: Modular chains for sharp edges in metal processing

- …

Occupational safety – circulation with magnetic pallets

SAFETY is a top priority for us and is adapted to your production application! Enclosed conveyor drives, the safely designed ErgoTek modular chain, magnetic workpiece holders – our options and ideas are diverse!

Watch the video to see our possibilities and ideas for yourself.

Talk to us!

We will be happy to advise you in order to find the optimum solution for your individual production application.