Doubling the finished part storage capacity through the use of vertical circulation storage

Due to increasing production figures and to reduce unit labor costs, individual production lines have to run 24 hours a day. Especially at weekends and during night shifts, when only part of the production can run with reduced operating personnel, production costs rise sharply.

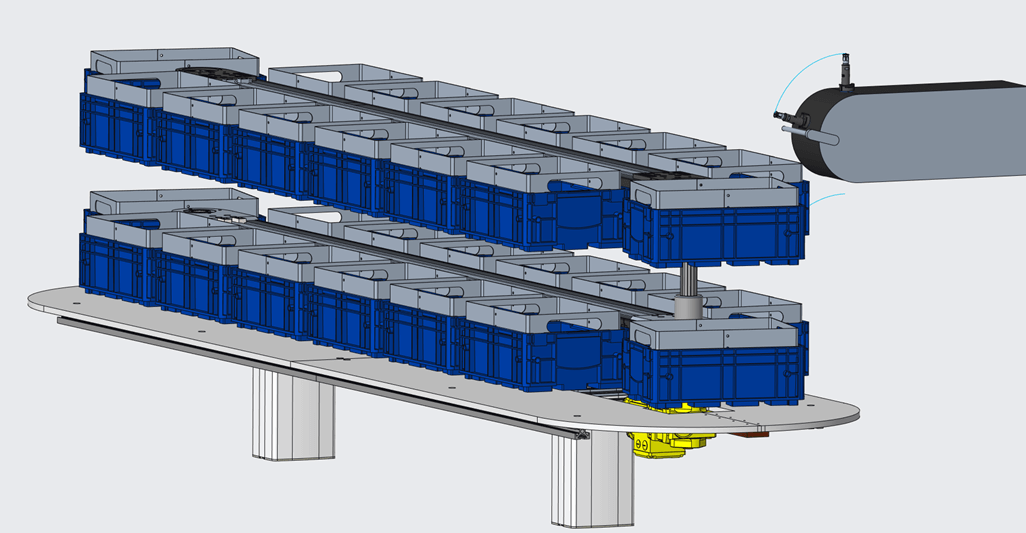

To cope with this situation, we have developed a circulation storage system for this individual production application that increases the storage capacity of the finished part storage and thus the effective, autonomous machine running time from 4 to 8 hours.

To achieve this long, self-sufficient machine runtime, the number of KLTs was doubled and the circulation storage distributed over 2 levels. An integrated lifting frame controls the loading of the small load carriers on both buffer levels fully automatically and alternately. The transfer of the main production line can remain unchanged thanks to the automatic lifting frame.

Here in the application equipped with 2x 14 KLTs.

Are you looking for special solutions for your individual production requirements?

Talk to us!

We also have a solution for your application with our modular and customized modular belt and cycle conveyors!