Customized feeding solutions for the automation of your production processes

We support you with customized individual solutions for the automation of your production processes.

Whether modular belt conveyors for feeding raw parts and returning finished parts or remnants or accumulating pallet circulation systems with individual workpiece carrier/workpiece holders, we adapt our modular conveyor systems individually and tailor-made to your production process and increase the efficiency and autonomous production time of your systems through adapted parts storage.

BEARING RING MACHINING

Requirement

- Turning of bearing rings up to Ø 280 mm

- Feeding the raw material as a blank

- Inner and outer ring from one sawing section

- Handling of rings Ø 70 to 280 mm

- Discharge sorted

- Residual piece return for further processing of the material

Solution

- Puma 2600 MSB for turning the bearing rings

- Automatic band saw with roller conveyor for feeding bar material up to 3000 mm

- KUKA KR70 R2100 with Schunk EMH 114-B magnetic gripper for handling the workpieces

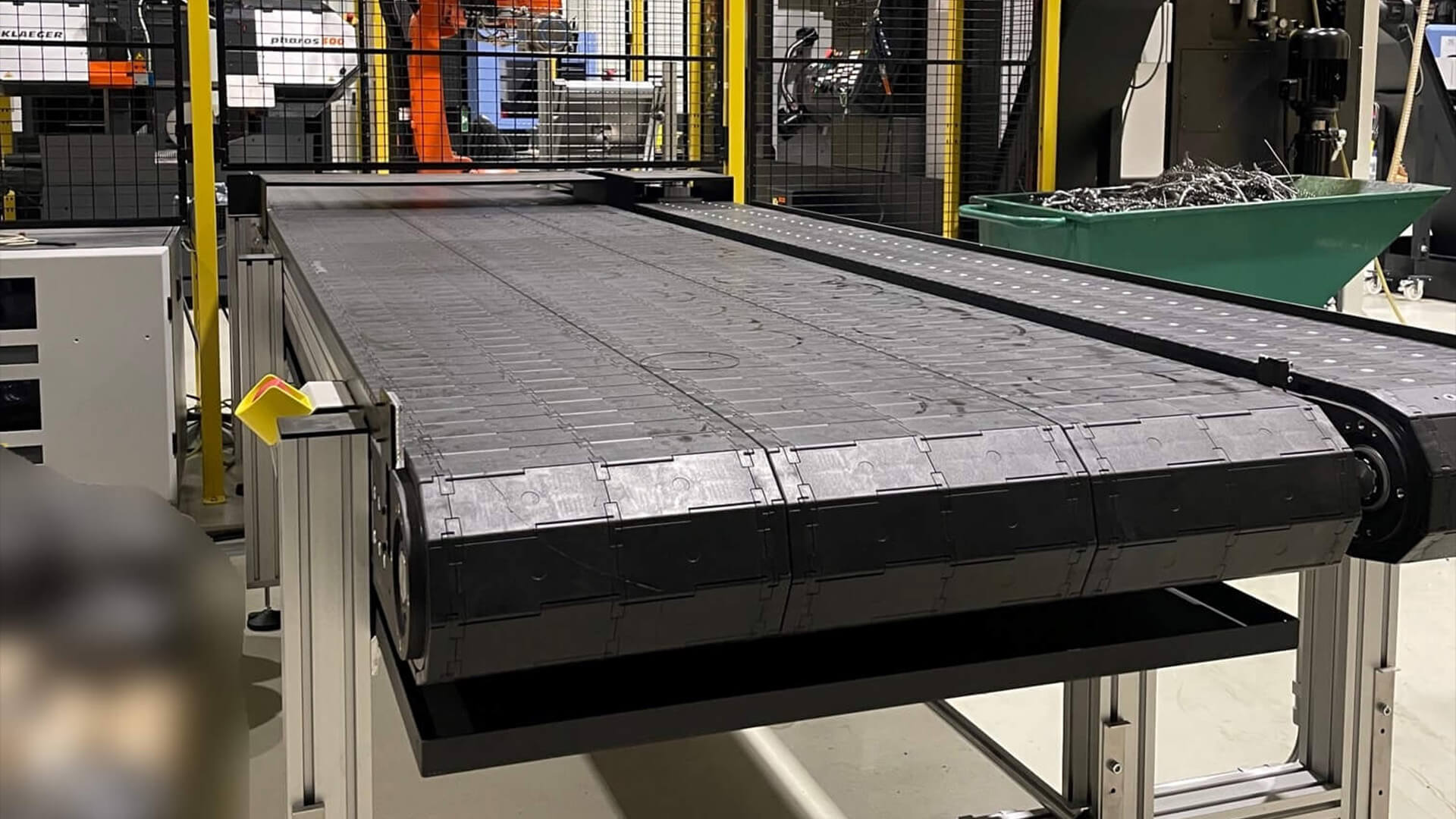

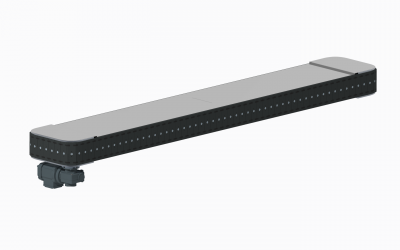

- ErgoTek modular belt conveyor MBF-P 55/120 for feeding the raw parts

- ErgoTek modular belt conveyor MBF-P 55/120 for returning finished parts and offcuts

- Siemens system control for user-friendly operation of the system

- Tool corrections of the lathe via HMI of the system control

* You will be redirected to the website of our partner Jörg Wappler Werkzeugmaschinen e.K..

Modular belt conveyor MBF-P 55/120 for feeding the raw parts

Modular belt conveyor MBF-P 55/120 with threaded inserts for attaching individual tool holders

PORTAL AUTOMATION

Requirement

- Double-sided turning of forged workpieces (gear shafts)

- Loading and unloading of the system independent of the cycle

- Parts memory for up to 4 hours of processing

- Blowing off the workpieces

- Ejection of SPC parts

- Permanent accessibility of the lathe guaranteed

Solution

- Puma TT 2500 SY for the turning of gear shafts

- Güdel linear gantry for loading and unloading the machine tool via the roof hatch

- Centric gripper with swivel unit to reach the main and counter spindles

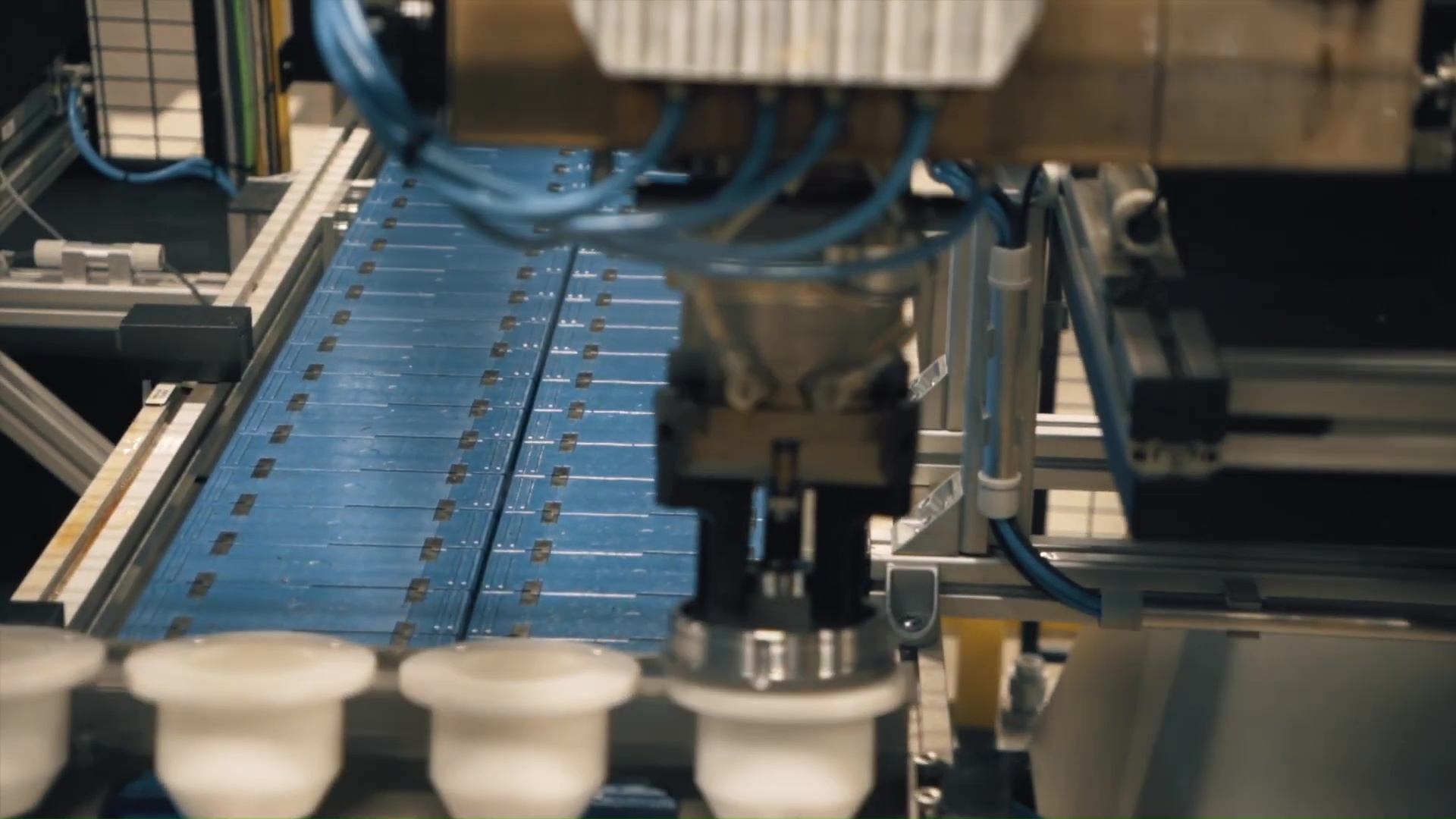

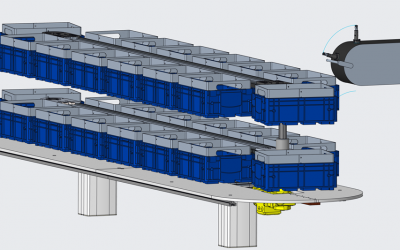

- ErgoTek accumulation conveyors from the FlexiTek-55 series, each with 22 individually manufactured workpiece carriers, each with 4 workpiece holders

- Linear axis for moving the SPC parts outwards

- Blow-off station with blower for energy-efficient blowing off of workpieces

- Siemens system control for user-friendly operation of the system

* You will be redirected to the website of our partner Jörg Wappler Werkzeugmaschinen e.K..

Individually manufactured tool holders

FlexiTek-55 accumulation conveyor

Also of interest to you? Talk to us!

We will be happy to advise you in order to find the optimum solution for your individual production application.