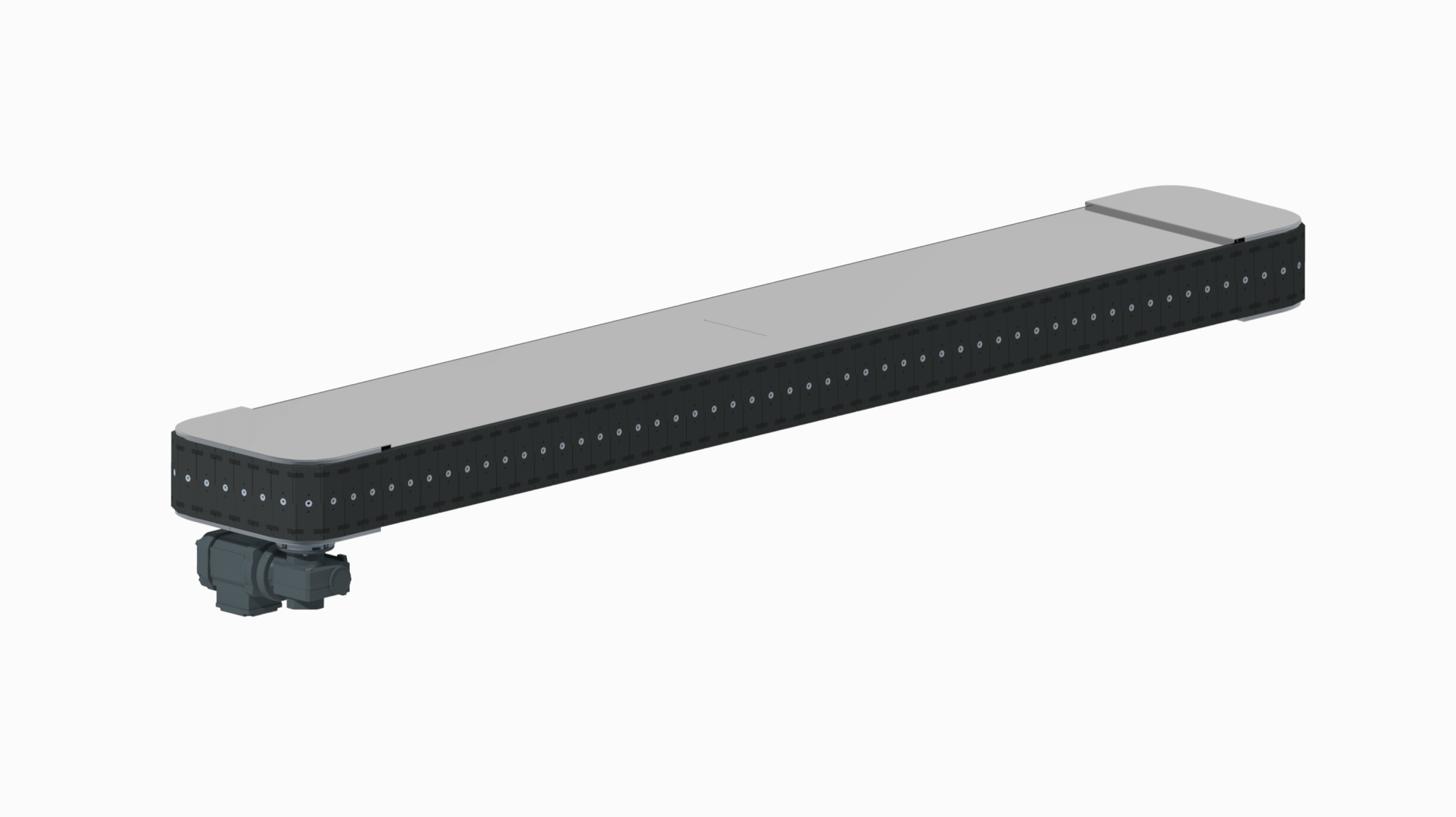

Indexing conveyor with variable length-to-width ratio:

MBF-P 55/120-4U conveyor system

The task:

Medical units are manufactured in the customer application. For this task, it must be ensured that transportation through the conveyor system is vibration-free and safe. To ensure that the automated production process can be operated economically in Europe, the system must be autonomous for at least 8 hours.

In order to be able to react to technical adjustments (size, design, capacity, etc.), the interlinking must guarantee a high degree of flexibility.

Integrating the conveyor system into the control system must be simple and straightforward.

The solution:

We have chosen our standard MBF-P 55/120 conveyor system as the basis for this special application. This ensures that different part holders are attached to the M8 threaded bushes. Additional index holes ensure anti-twist protection and precise alignment.

The number and size of the part holders determine the length of the system, making it easy to scale the chain pitch.

This also means that the part holders can be replaced quickly and easily if adjustments are made to the product.

A three-phase asynchronous motor with frequency converter ensures smooth and safe transportation. The “In division” message is sent via an initiator.

If future applications require a change in the distance and number of part holders, no intervention in the control system or programming will be necessary.

The customer advantage:

- Simple integration into the control system

- Low maintenance and free of lubricants

- Flexibly customizable

- Safe to use

We would like to thank everyone involved in the project for the great collaboration!

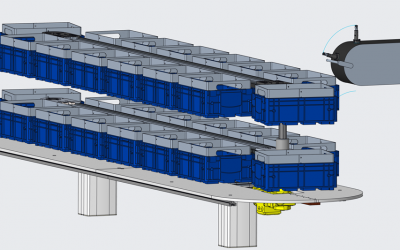

You can find another example on LinkedIn for a 4-lane circulation system based on MBF-P 80/120-4U